Jelly Gummy Candy Ua Tshuab

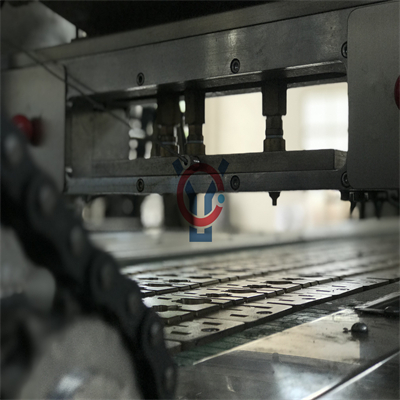

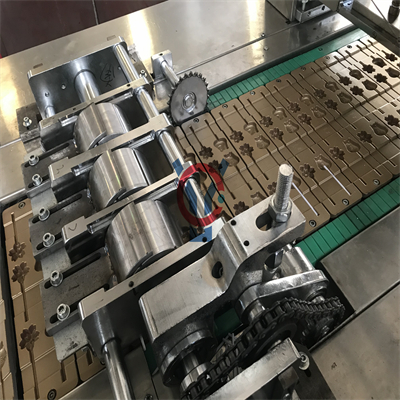

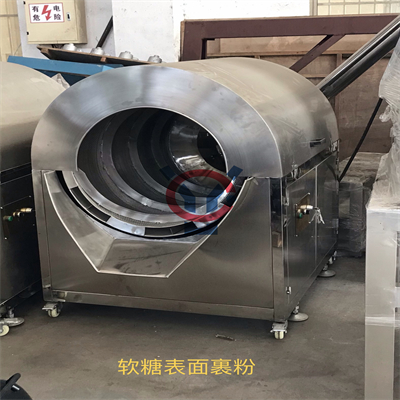

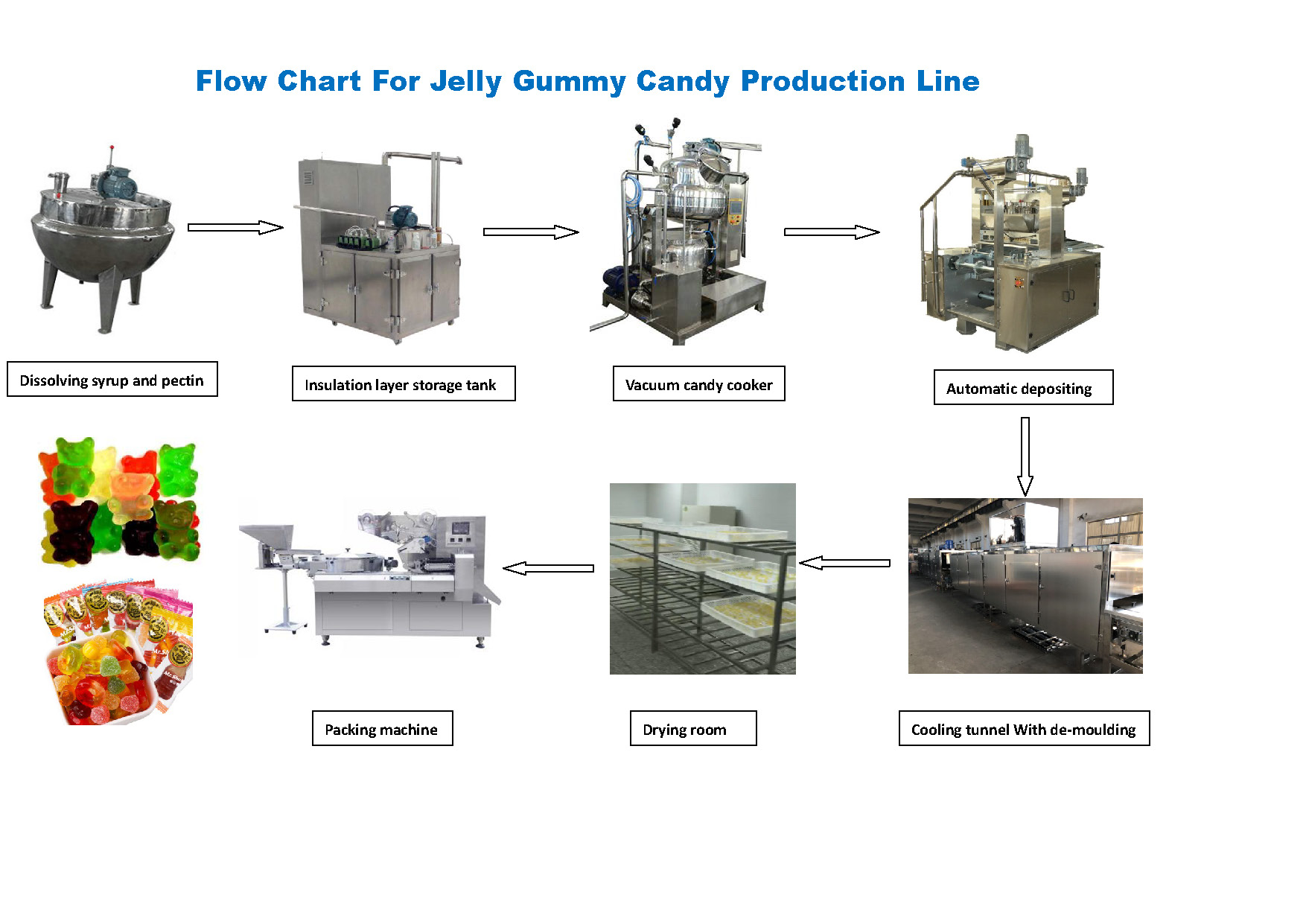

Gummy (Jelly) khoom qab zib ua kab yog ib qho kev cog qoob loo siab heev thiab txuas ntxiv mus ua ntau qhov sib txawv ntawm jelly candies (QQ candies) nws yog ib qho khoom siv zoo tshaj plaws uas tuaj yeem tsim tawm cov khoom zoo nrog kev txuag ntawm ob qho tib si cov neeg ua haujlwm thiab qhov chaw nyob. Qhov no gummy khoom qab zib depositing kab muaj lub tsho dissolving cooker, iav twj tso kua mis, cia tank, cia, tso tawm twj tso kua mis, cia tank, tso twj tso kua mis, xim & tsw tov khoom, depositor, txias qhov, txias qhov, hluav taws xob tswj txee, thiab lwm yam.

Technical Specifications

| Qauv | YGDQ50-80 | YOG 150 | YOG 300 | YGQ450 | YOG 600 |

| Muaj peev xwm | 15-80kg / h | 150kg / h | 300kg / h | 450kg / h | 600kg / h |

| Khoom qab zib hnyav | raws li cov khoom qab zib loj | ||||

| Depositing ceev | 20-50n / min | 35-55n / min | 35-55n / min | 35-55n / min | 35-55n / min |

| Chav yuav tsum | 250kg / h,0.5 ~ 0.8 Mpa | 300kg / h,0.5 ~ 0.8 Mpa | 400kg / h,0.5 ~ 0.8 Mpa | 500kg / h,0.5 ~ 0.8 Mpa | |

| Compressed cua xav tau | 0.2 m³ / min0.4 ~ 0.6 Mpa | 0.2 m³ / min0.4 ~ 0.6 Mpa | 0.25 m³ / min0.4 ~ 0.6 Mpa | 0.3 m³ / min0.4 ~ 0.6 Mpa | |

| Kev Ua Haujlwm | Kub: 20 ~ 25 ℃ ; n / Humidity: 55% | ||||

| Tag nrho lub zog | 6 kws | 18Kw / 380V lub cev muaj zog | 27Kw / 380V lub cev muaj zog | 34 Kw / 380V | 38 Kw / 380V |

| Tag Nrho Ntev | 1 'meter' | 14m ua | 14m ua | 14m ua | 14m ua |

| Qhov hnyav tag nrho | 300 kg | 3500kg ib | 4000 kg | 4500kg ib | 5000 kg |

Sau koj cov lus ntawm no thiab xa tuaj rau peb